Concrete Curing Agent MT-700

Aiddem MT-700 High-efficiency Concrete Curing Agent is an advanced solution that improves concrete curing efficiency and strength retention. With its rapid film formation and excellent moisture retention properties, it reduces water usage by up to 80%, offering both environmental and economic benefits while enhancing concrete durability.

MT-700 is a next-generation eco-friendly curing agent that forms a breathable film on concrete surfaces. This film prevents moisture evaporation, reduces shrinkage cracks, and promotes continued hydration, significantly enhancing concrete's strength and durability.

MT-700 High-efficiency Concrete Curing Agent

▋Description :

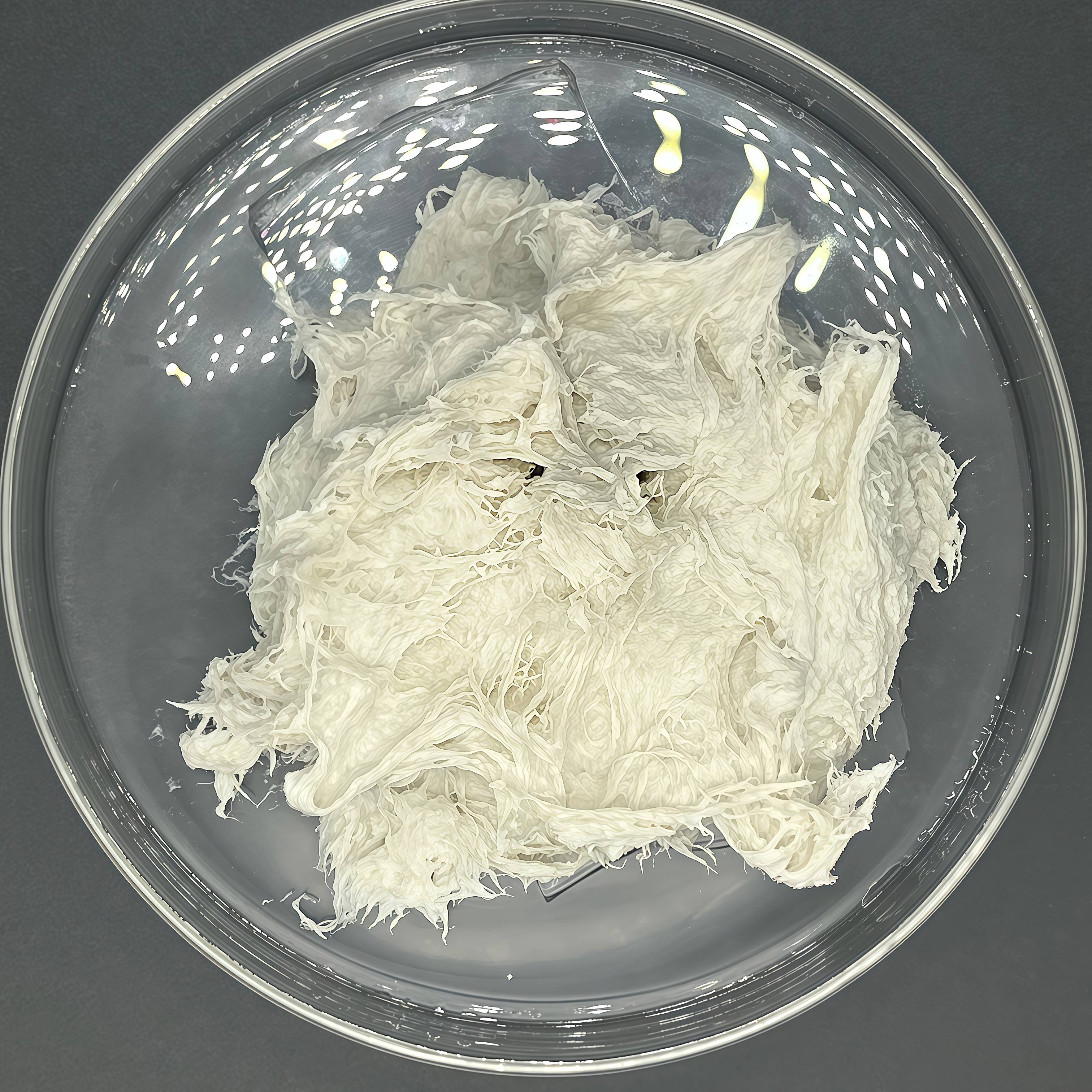

MT-700 High-efficiency Concrete Curing Agent is a new generation of eco-friendly curing material, developed with advanced nano film-forming technology that surpasses the performance limitations of traditional curing agents. It forms a dense and breathable protective film, 1–3 microns thick, on the surface of the concrete.

This film effectively prevents moisture evaporation, significantly reduces plastic shrinkage cracks, while allowing

CO₂to slowly permeate, promoting continued cement hydration and enhancing the strength and durability of the concrete.

▋Advantages :

●Construction Advantages: One-time application replaces traditional water curing; excellent oxidation stability, suitable for pond immersion curing;

●Film Formation Efficiency: Surface drying time is only 30-40 minutes, film formation time is 2-3 hours, which is approximately 30% shorter than industry standards;

●Performance Breakthrough: 7-day compressive strength reaches 96%, and the 28-day strength retention rate is 99%, exceeding national first-class product standards;

●Appearance Quality: The film is colorless and transparent, ensuring uniform appearance of the components with no color difference, no stickiness, no slipping, and no yellowing;

●Durability Enhancement: Blocks chloride ion penetration, reduces carbonation rate, and extends structural lifespan by 20-30%;

●Ecological Benefits: Saves 70%-80% water compared to traditional water curing, and does not affect the adhesion of subsequent decorative layers;

●Economic Benefits: Reduces traditional water curing processes, lowering overall costs by 30%-40%;

●Low Emission Standards: VOC content is <30g/L (EU EN 16516 standard); no heavy metals or formaldehyde additives.

▋Application Guide :

●Recommended Dilution Ratio: Water to agent ratio of 1:1 to 1:2, adjust based on actual application conditions;

●Application Method: Can be mechanically sprayed (0.3-0.5 MPa pressure) or immersed, with a coverage rate of 40-50㎡/kg;

●Consumption Reference: 0.017-0.02 kg/m² (depending on the specific construction process);

●Application Scenarios: Suitable for curing of cast-in-place concrete, precast components, tunnel segments, road bridges, and other similar applications.

▋Product data :

Item

MT-700

China Building Materials Industry Standard JC901-2002(2009) Qualification Standard

Effective Water Retention Rate (%)

91%

≧75

Compressive Strength Ratio

7 days

96%

≧90

28 days

99%

≧90

Wear Amount (kg/m²)

2.78

≦3.5

Drying Time (hours)

2.9

≦4

Film Water Solubility after Formation

Insoluble

Should indicate whether soluble or insoluble

Film Heat Resistance

No melting, no discoloration

No melting, no discoloration

☆ The product testing is based on the "China Building Materials Industry Standard JC901-2002(2009)," with data sourced from a third-party testing agency.

▋Pack size :

● 20KG/50KG/200KG/1,000KG per drum,in Eco-friendly barrel packaging.

▋Storage and Transport :

● Shelf Life: 12 months (unopened);

● Storage: Store in a cool, ventilated place, avoid freeze-thaw cycles;

● Transportation: In accordance with GB/T191 standard, protect from rain and sunlight.