The Importance of Concrete Release Agents in Precast Concrete Production

The Importance of Concrete Release Agents in Precast Concrete Production

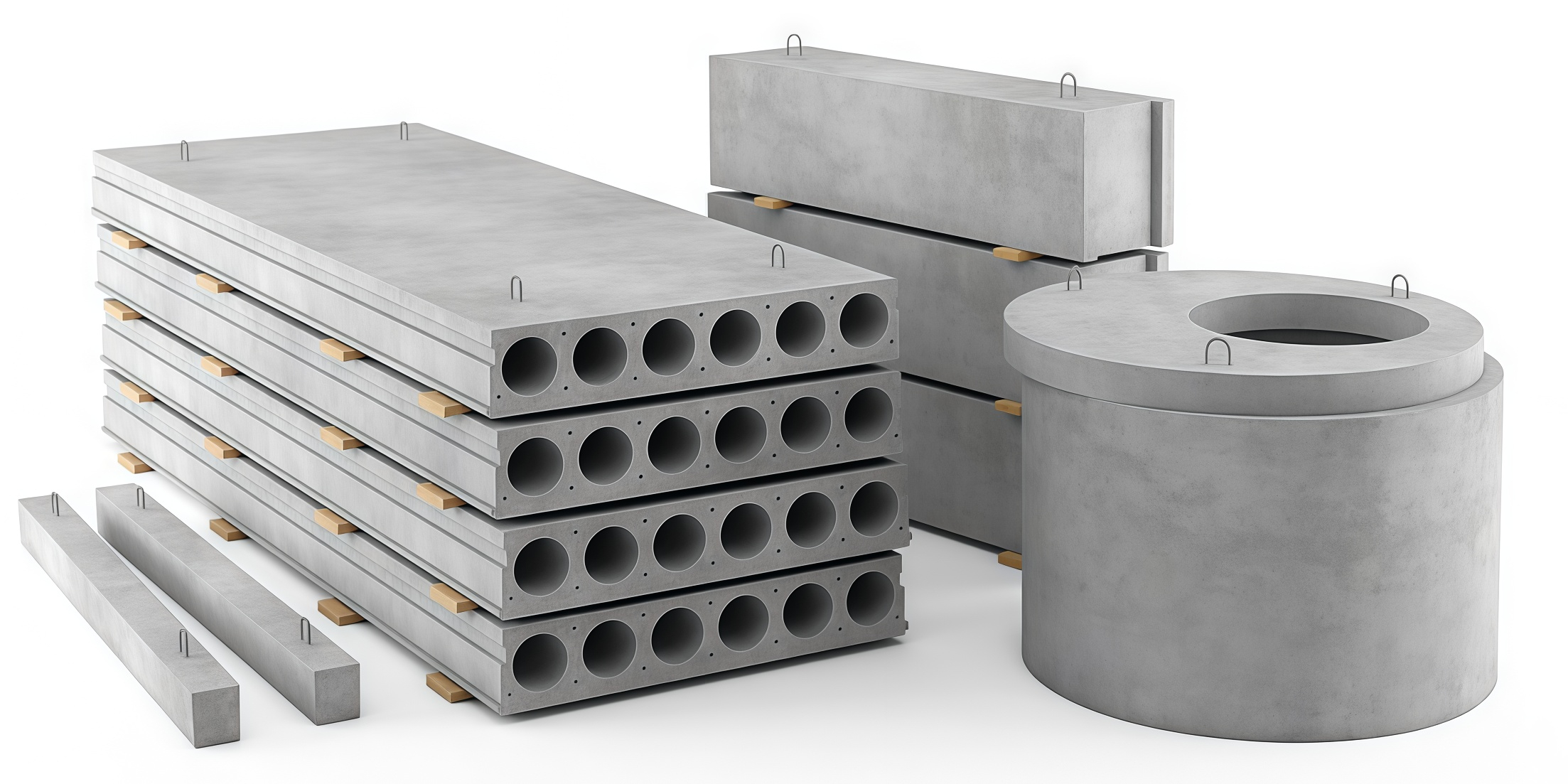

In the world of construction, precast concrete is a popular choice for its durability and efficiency. However, one of the key challenges in precast concrete production is ensuring easy demolding while maintaining high-quality surface finishes. This is where concrete release agents come in. In this blog, we’ll explore the importance of concrete release agents in precast concrete production and how they help improve both efficiency and the final product quality.

1. Why Concrete Release Agents Are Essential

Concrete release agents are used to prevent concrete from sticking to molds, allowing for easy and clean removal once the concrete has set. They are especially important in the production of precast concrete elements like beams, panels, and columns, where a smooth and defect-free surface is crucial. A good release agent helps improve the efficiency of production while reducing the risk of surface damage and mold wear.

2. Choosing the Right Concrete Release Agent

When selecting a concrete release agent, it’s important to consider the type of molds used, the concrete mix, and the environmental conditions. There are both chemical-based and oil-based release agents, each suited to different types of molds and applications. The right choice ensures smooth demolding without leaving residue or affecting the concrete’s quality.

3. Aiddem’s Concrete Release Agents

Aiddem offers high-performance concrete release agents designed to meet the specific needs of precast concrete production. Our products not only make demolding easier but also improve the surface quality of the finished product, ensuring fewer defects and a longer mold lifespan. Whether you’re working with steel, aluminum, or plastic molds, we have the right solution for you.