T-701 TBM Tail Sealing Grease

Aiddem T-701 TBM Tail Sealing Grease delivers exceptional sealing and lubrication for shield tunneling operations, preventing water leakage and mortar infiltration. It offers excellent resistance to water impact, adhesion, and pumpability across a wide temperature range.

T-701 TBM Tail Sealing Grease is a uniform paste used in shield tunneling, offering excellent sealing, waterproofing, and lubrication. It provides strong resistance to water impact and ensures smooth operation between the segment and shield tail.

T-701 TBM Tail Sealing Grease

▋Description :

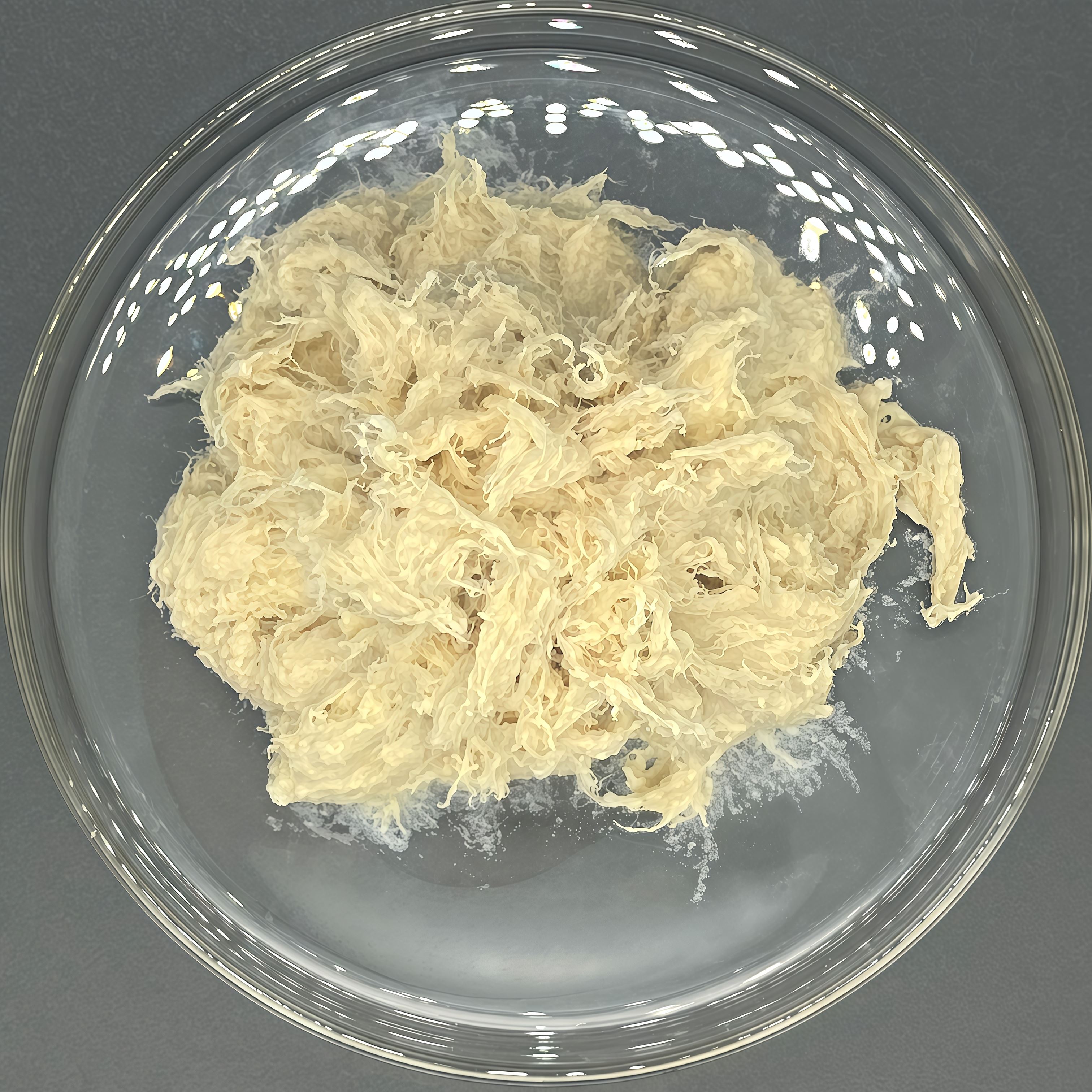

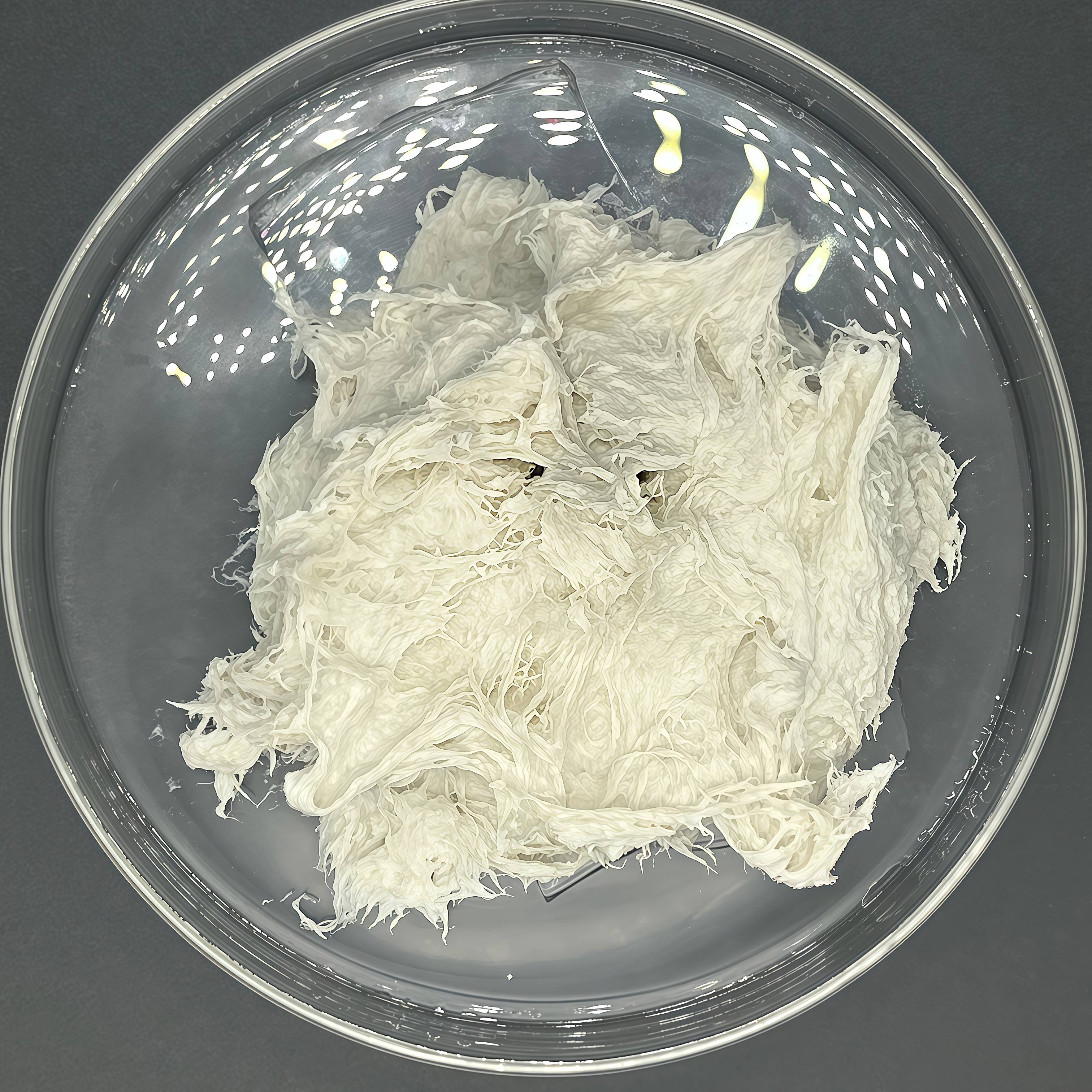

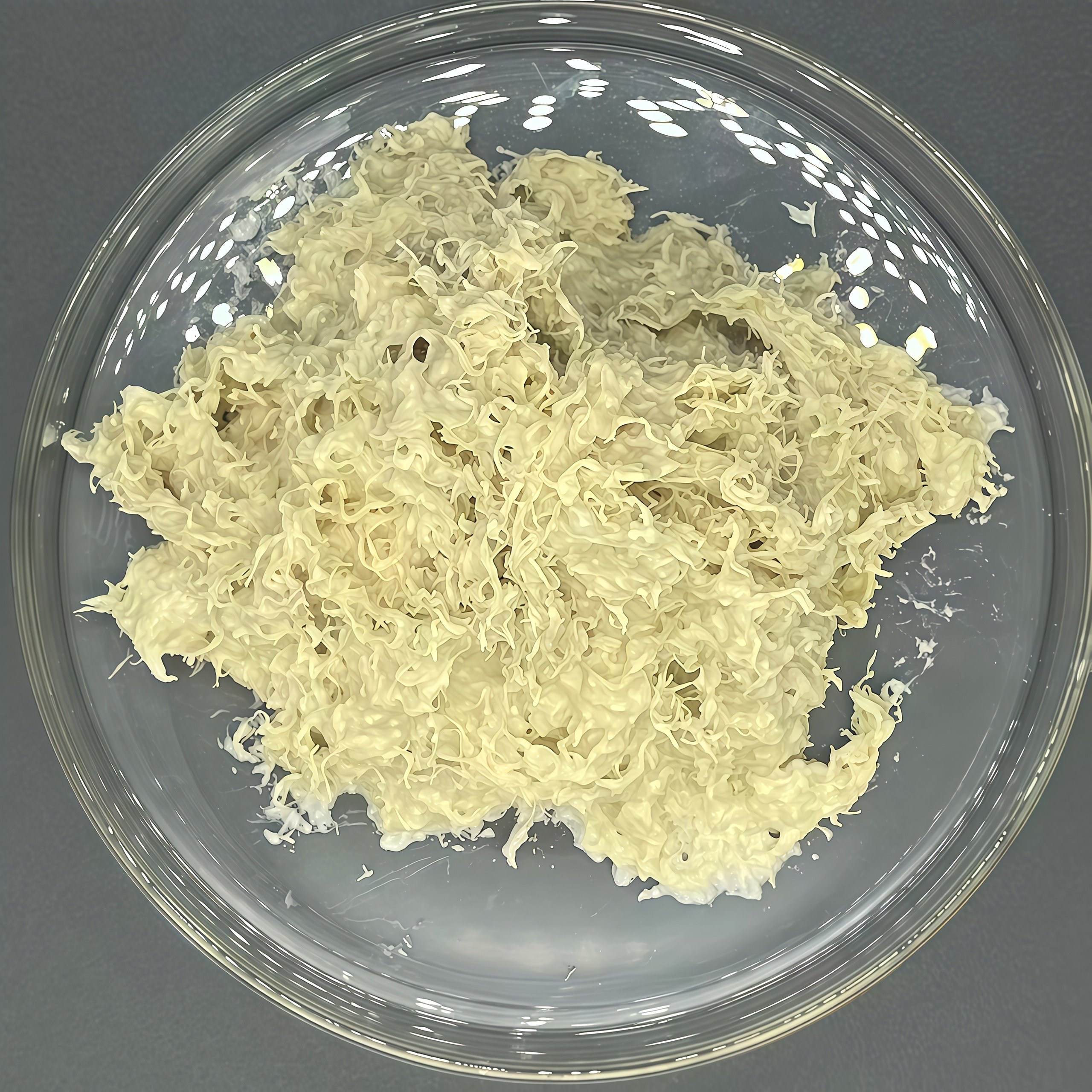

T-701 TBM Tail Sealing Grease is a uniform paste formulated through a special process using fibers, tackifiers, fillers, sealants, and other components. Its main function is to provide sealing, waterproofing, and lubrication during shield tunneling operations.

▋Application :

●Prevents external grout and groundwater from penetrating into the shield machine;

●When the segment exits the shield tail, a layer of grease is applied to the outer side of the segment to reduce friction between the segment and the shield tail.

▋Features :

●Excellent water-resistant sealing properties;

●Excellent lubrication properties;

●Good pumpability over a wide temperature range;

●Good resistance to water impact;

●Excellent adhesion.

▋Product data :

|

Item |

Typical Data |

|

|

Pumping Type |

Manual Coating Type |

|

|

Appearance (Visual) |

Yellow fibrous uniform grease |

Yellow fibrous uniform grease |

|

Metal Corrosion Resistance, applied to iron plate at room temperature (30 days) |

Non-corrosive |

Non-corrosive |

|

Penetration, 0.1mm |

220–270 |

210–230 |

|

Evaporation Rate (80°C, 5h), % |

≤2.5 |

≤2.5 |

|

Density (25°C, g/cm³) |

1.3 |

1.3 |

|

Pumpability (25°C, 8 bar, g/min) |

≥20 |

- |

|

Water-resistant Sealing (25°C, 20 mesh sieve, 3.5 MPa, 1 hour) |

No water leakage |

No water leakage |

|

Adhesion (At 25℃, two 120*120*5 steel plates, sliding displacement in 10 minutes) |

≤10 mm |

≤10 mm |

▋Pack size :

● 250KG per drum, with custom packaging available upon request.

▋Precautions :

● Before use, clean the lubricating parts thoroughly and allow them to dry before applying this product.

● After use, make sure to seal the cap tightly to prevent contamination from foreign particles.

● Do not mix with other greases to avoid affecting performance.

● Store the product in a clean, dry, and light-protected area.